Heavy duty vehicles do requires heavy duty equipment. Though the choice totally depends upon on the factors which including configuration of the vehicle, types of parts, damaged engine and time required for its replacement.

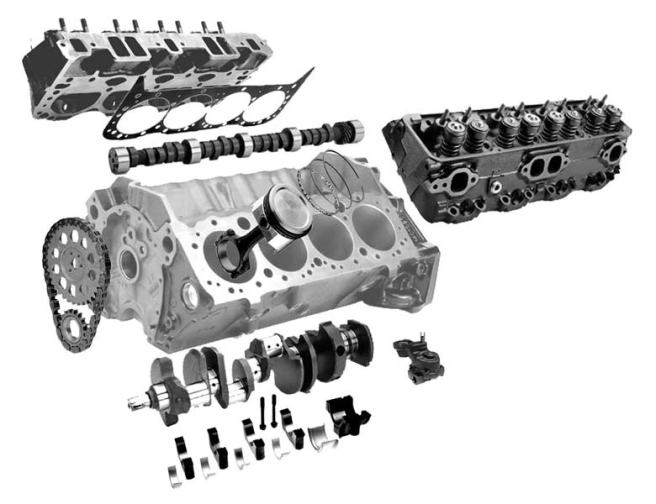

Sometimes a motor block replacement comes up due to loose bearings. When it rotates, it may cause a broken connecting rod leading to a breakage and punches side-wise. At times the connecting rod punches cylinder head too. In this situation, the entire engine components are in their ideal for working but the bottom requires a quick replacement. The bottom section is actually known as the short block. The larger tractor engines are made up of four major components and several smaller parts and other accessories attached externally.

In a tractor, the short block engine has two things common the cylinder block and the crankcase. When we talk about the automotive field in which small engines, the crankcase and the cylinder block is used as a single casting. The cylinder liners, the piston assembly and the camshaft are housed in the cylinder sleeve. The top most part of the cylinder block is called the combustion chamber. The cylinder head is bolted on the top of this assembly which is not a part of the short block engine.

The crankcase is the bottom section of the short block engine which houses the crankshaft, crank seals, bearings and front gear train. And the perfect combination of the cylinder block and the crankcase is known as the short engine block. These two perfect parts are welded together and also internally connected using connecting rods.

The piston pin says that the main power is transferred from the movements of the piston to the crankshaft using connecting rods. Removed from the salvaged tractor yards, the shorter blocks are called good used short blocks. After complete replacement of the components, the functionality of the tractor motor is checked and approved to be used in the field.

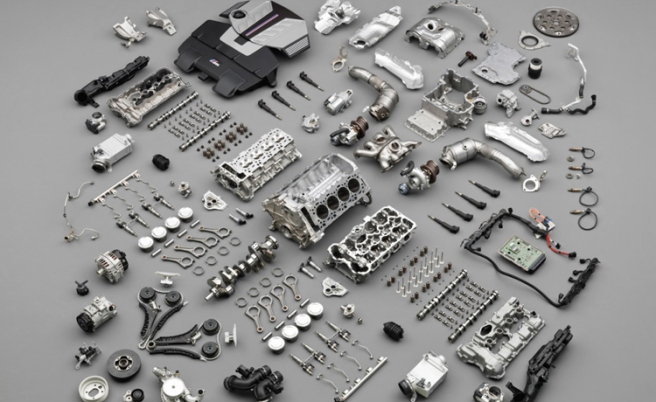

Summary: Engine parts are necessary for the smooth functioning of machines and vehicles. Manufactures have wide range of automobile engine parts for almost all vivid kinds of models and in variant sizes from small to large.